Design/Engineering

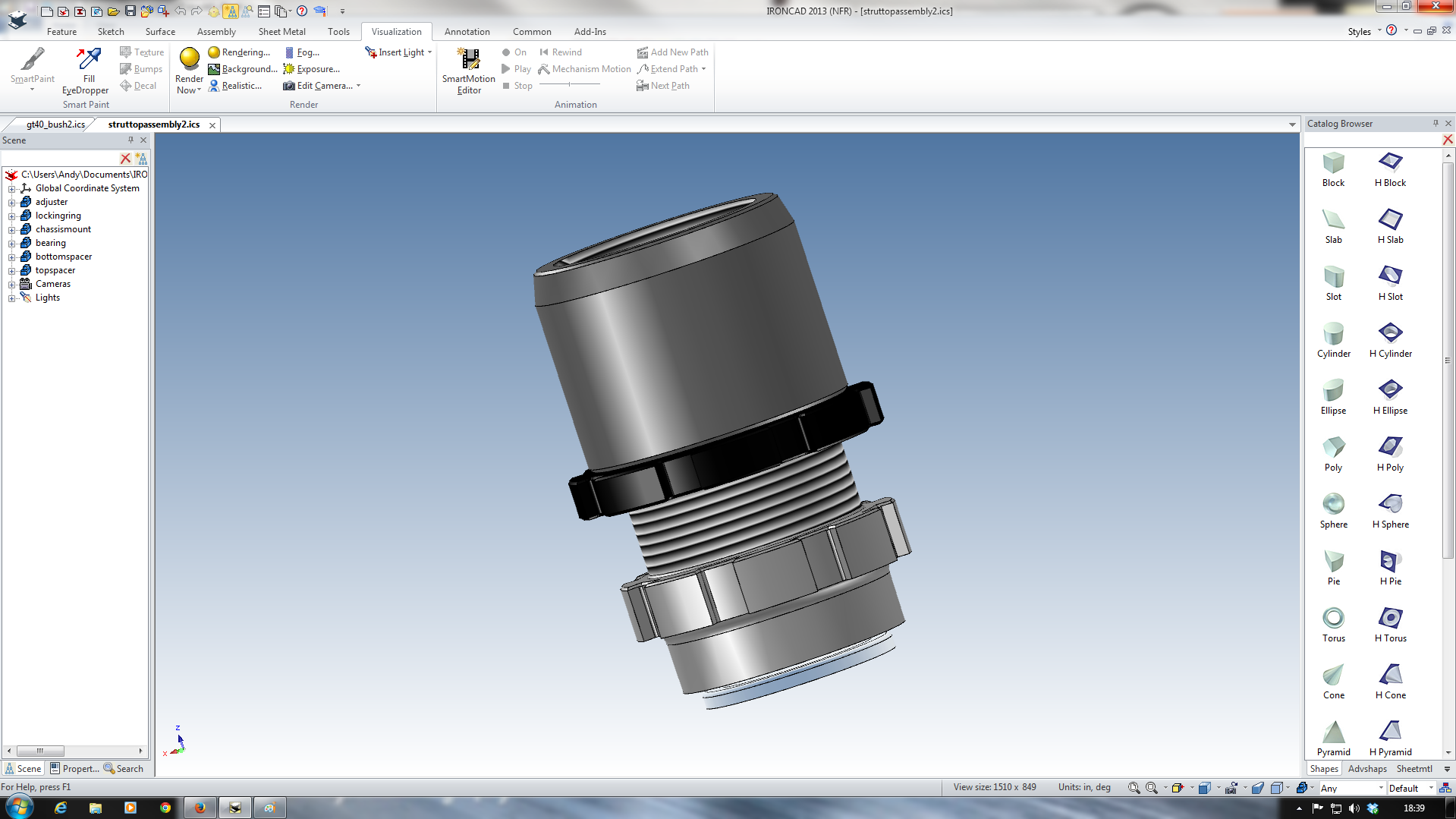

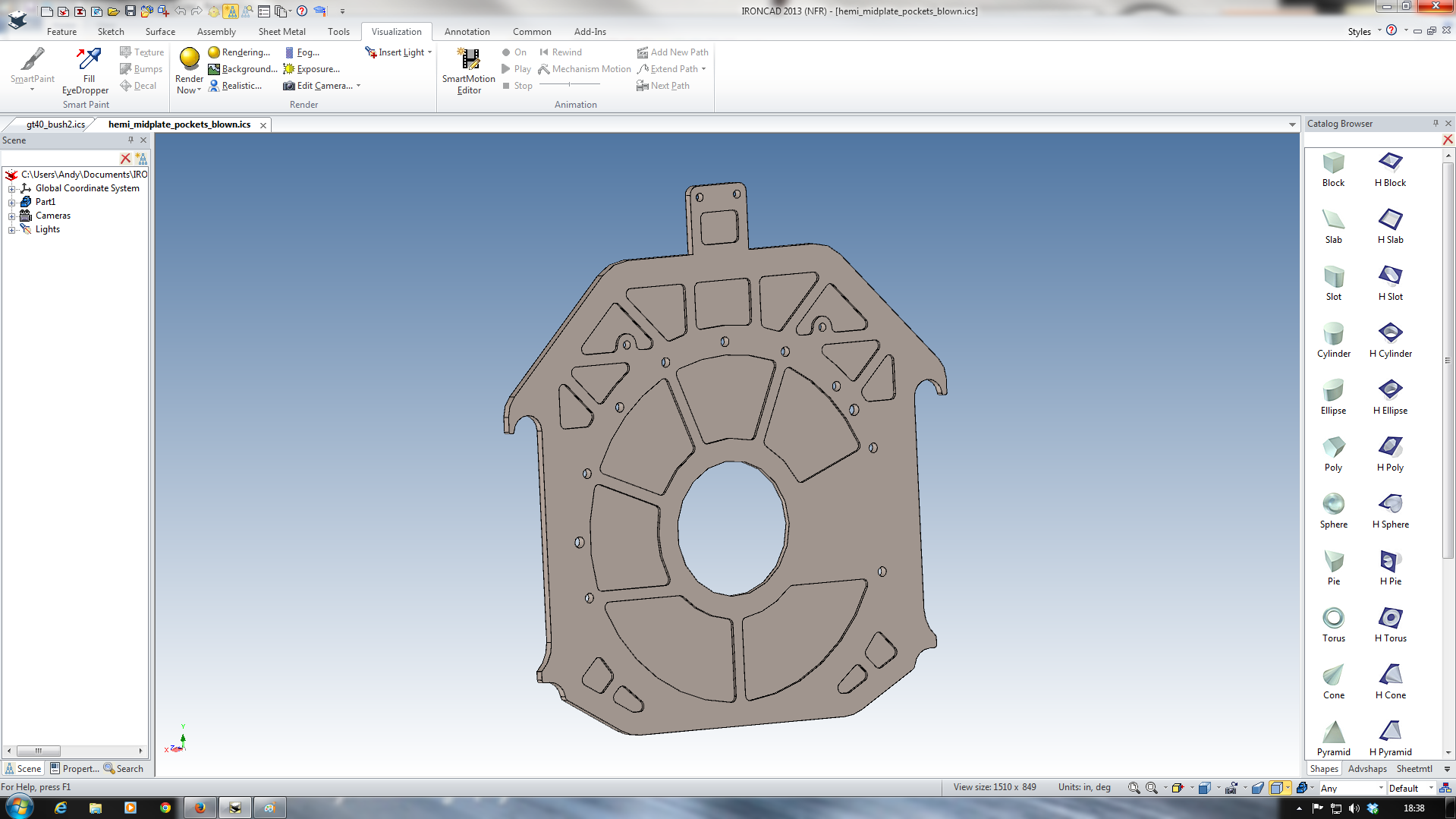

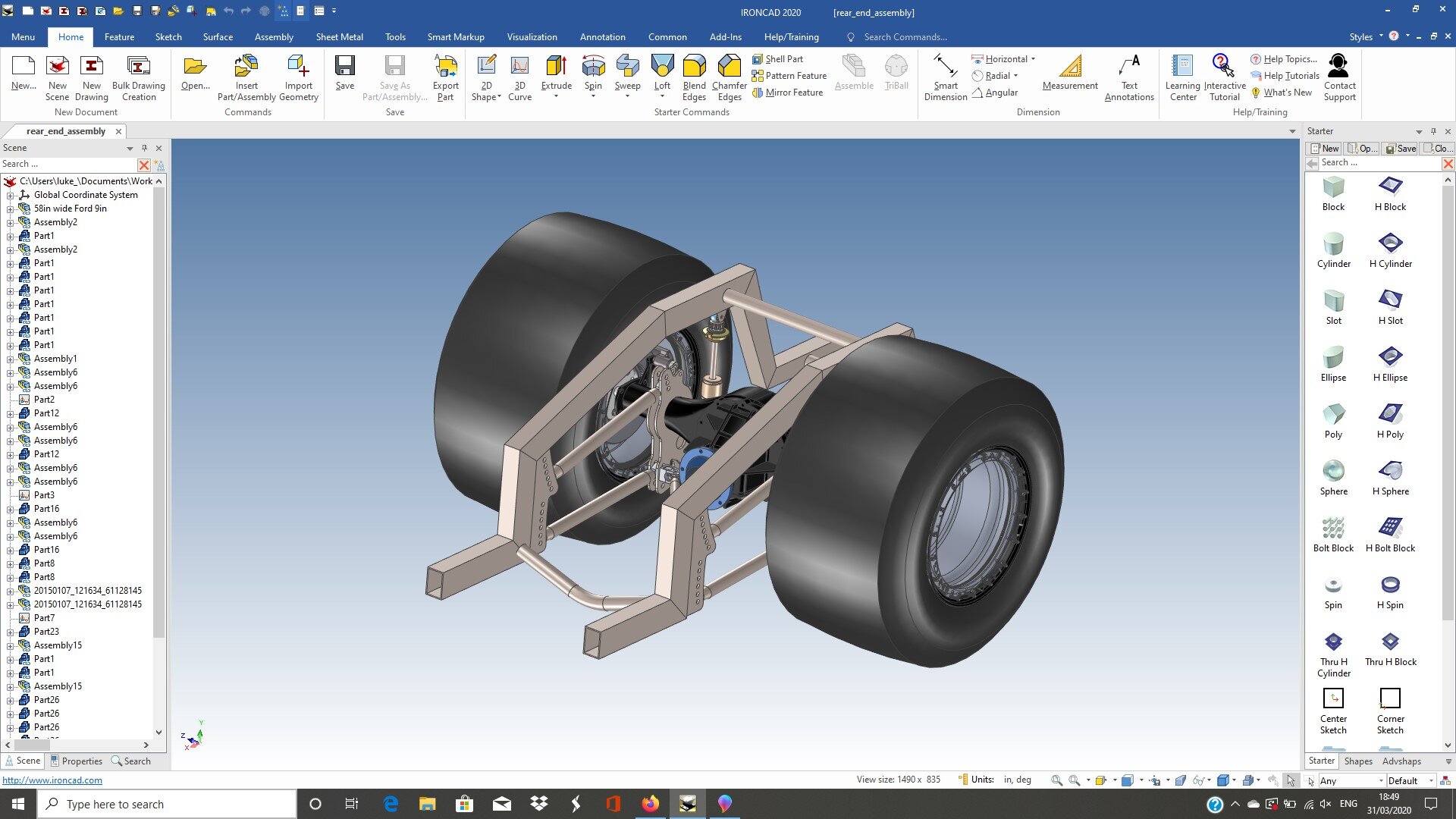

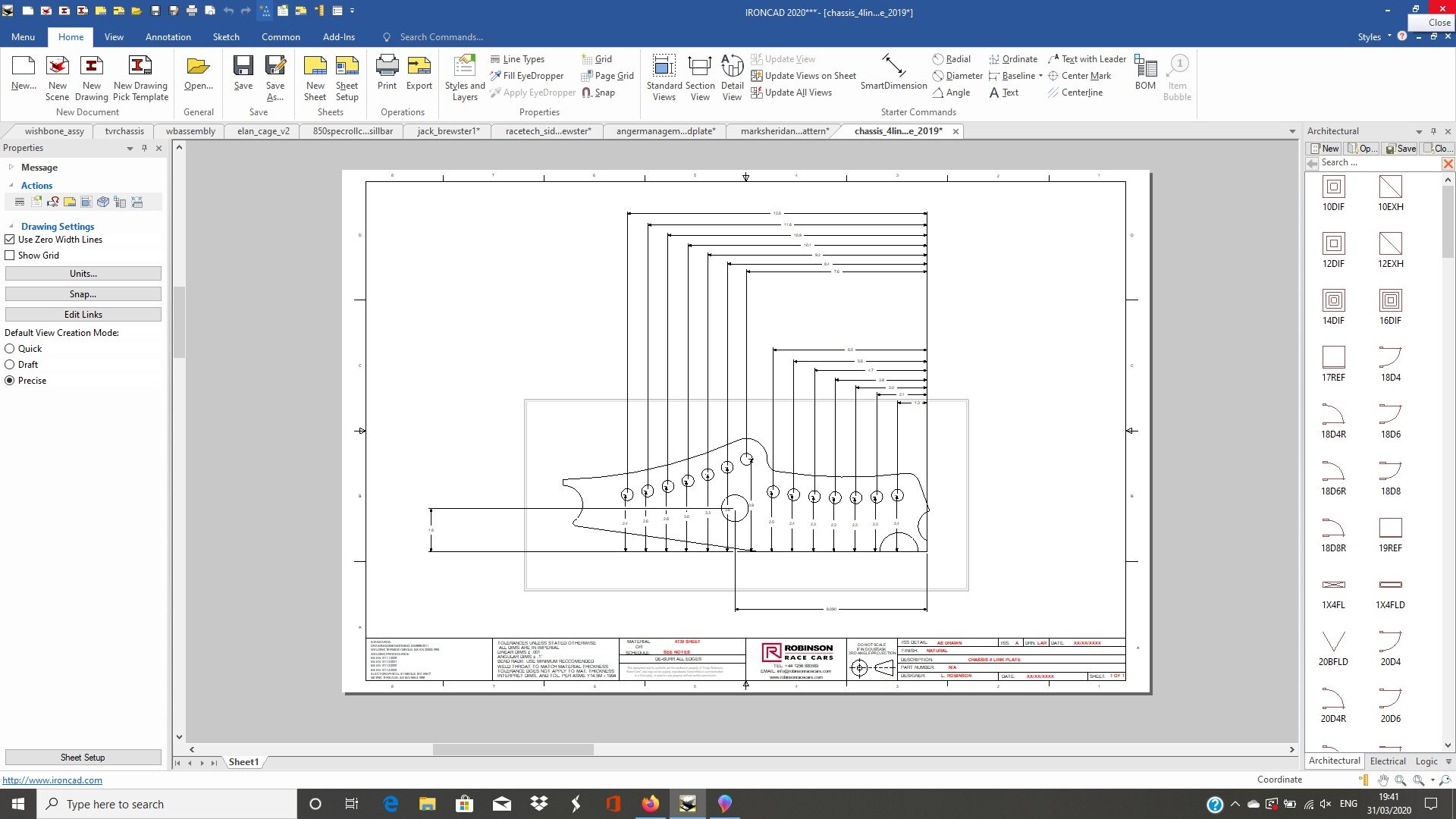

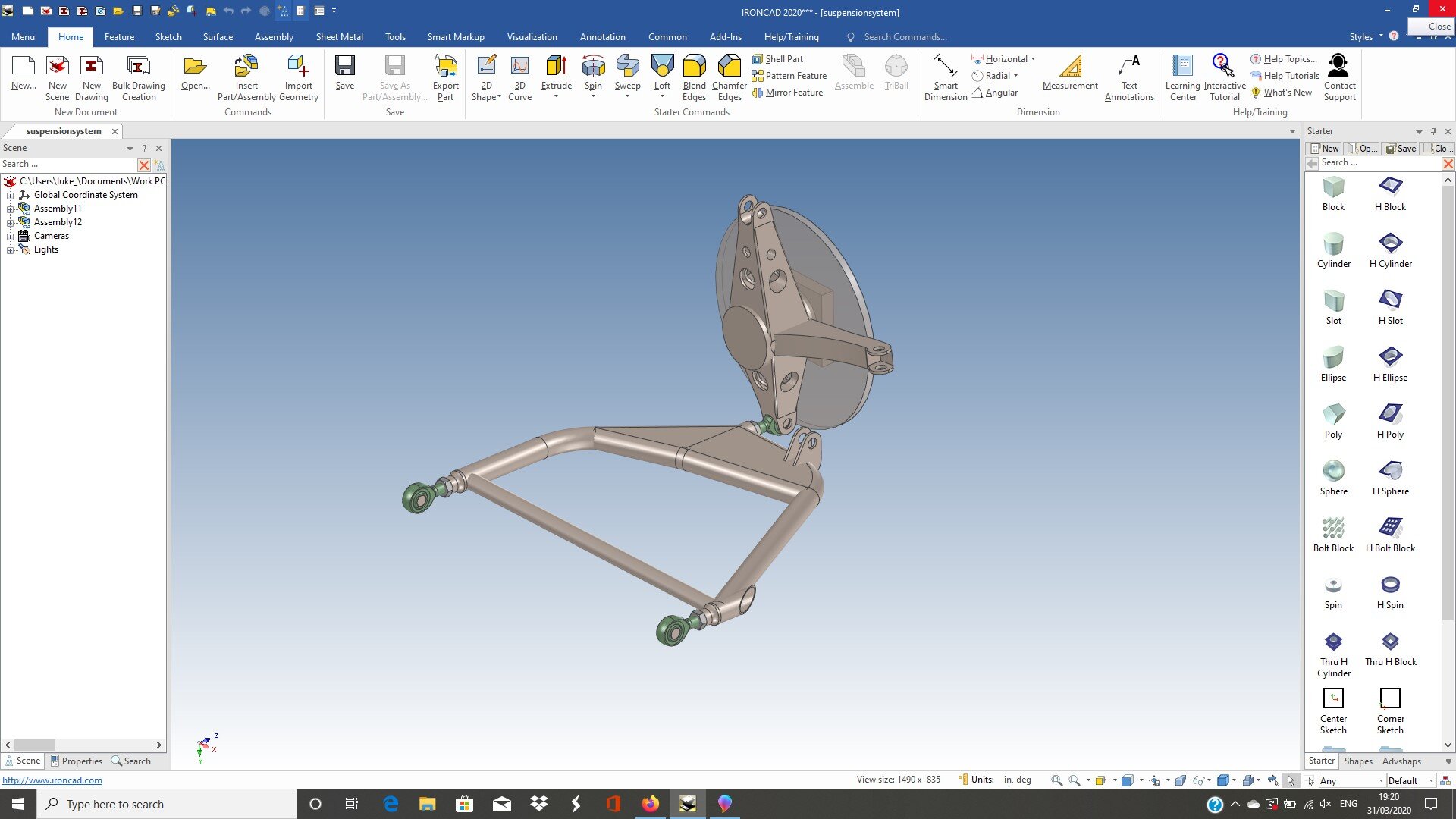

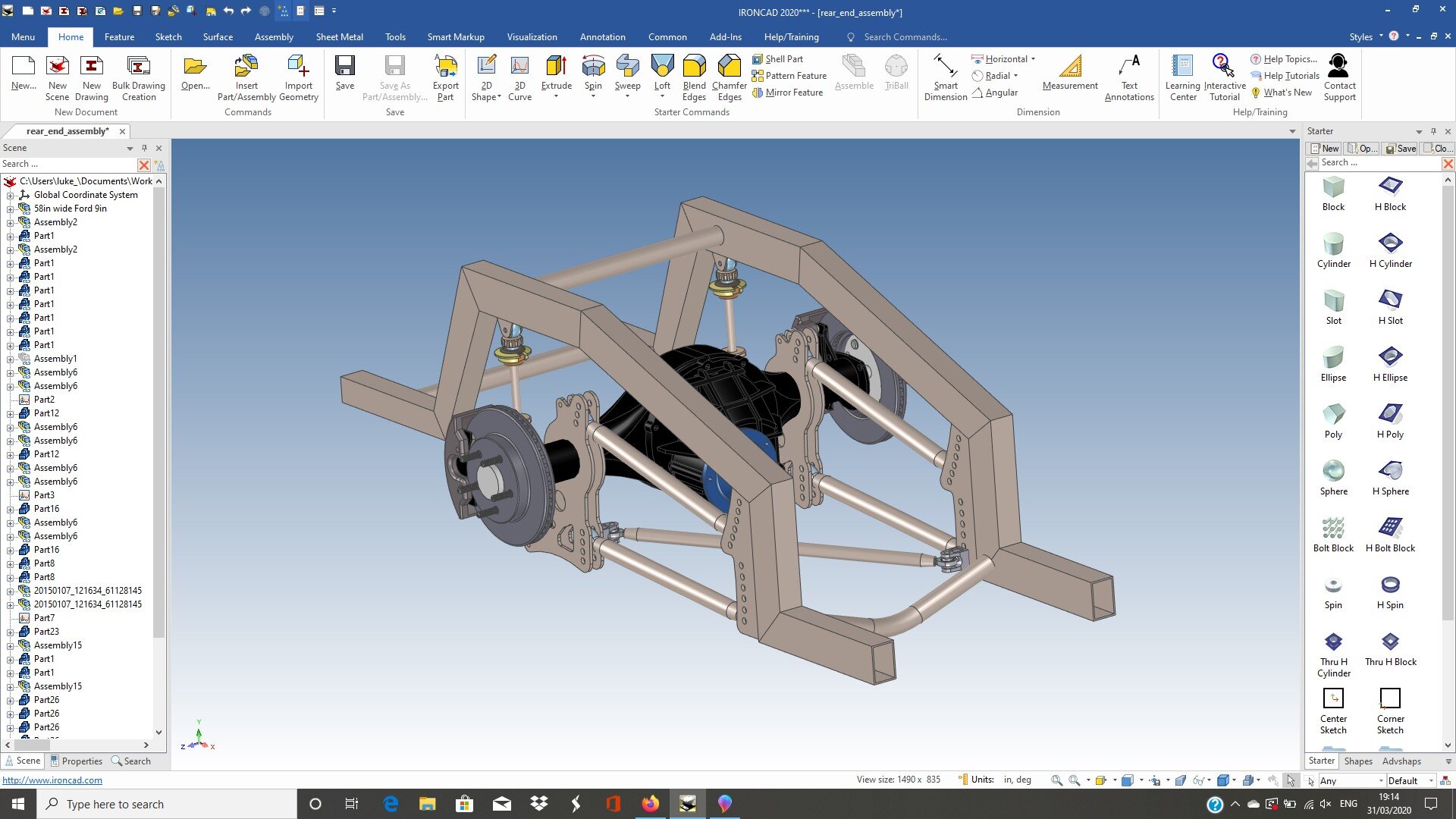

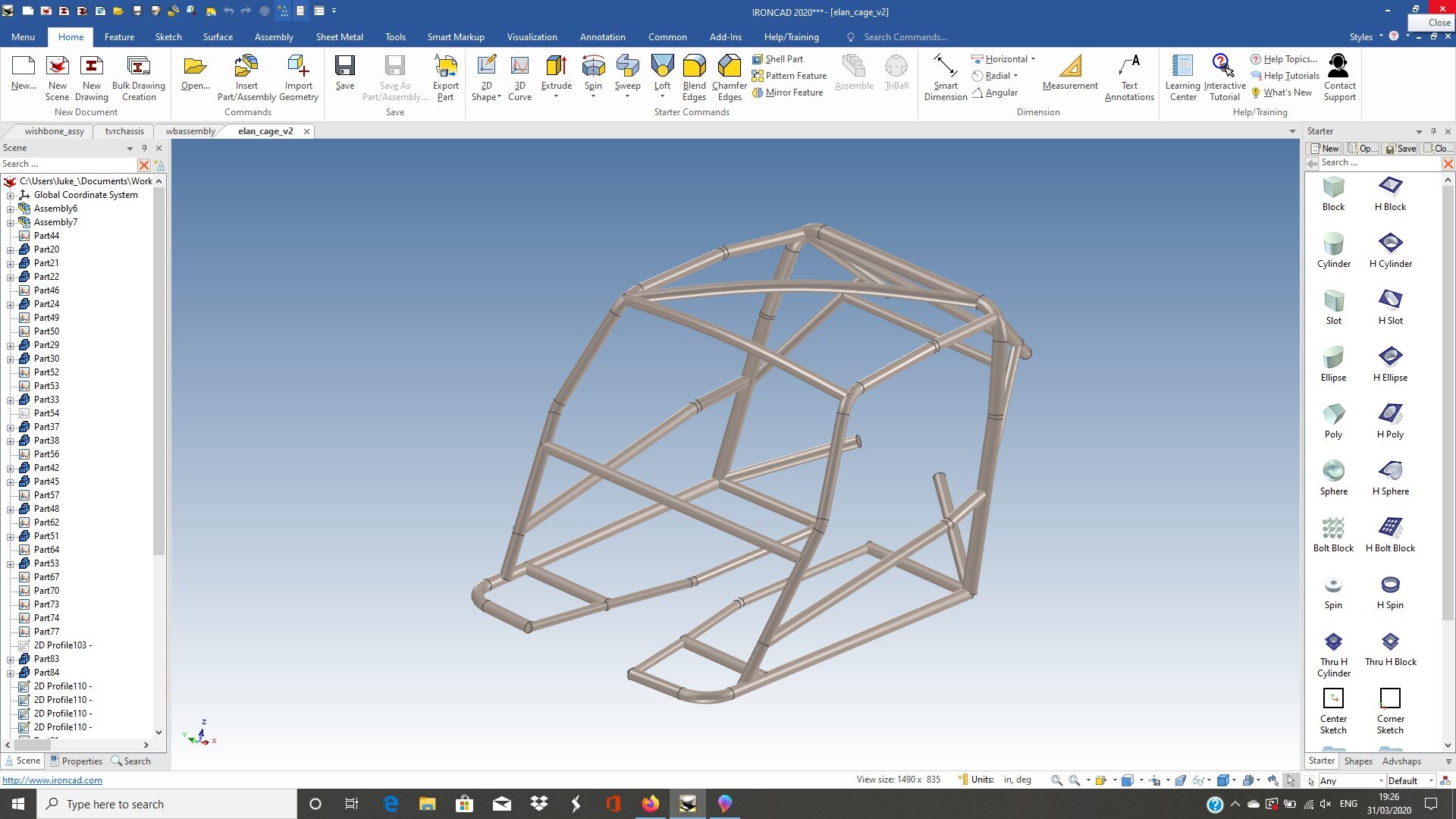

At Robinson Race Cars, we exclusively use IronCad for all our design work. IronCad facilitates both Parametric and Direct Modeling design paradigms, as well as powerful 2D sketch features. This allows us to build solid models of components to be CNC machined, 3D assemblies of integrated systems (click here for a good example of this) and also 2D sketches of bracketry which can either be subcontracted to our laser cutter, or in the case of small volume or ‘one off’s’ cut using our in house CNC Plasma Cutter.

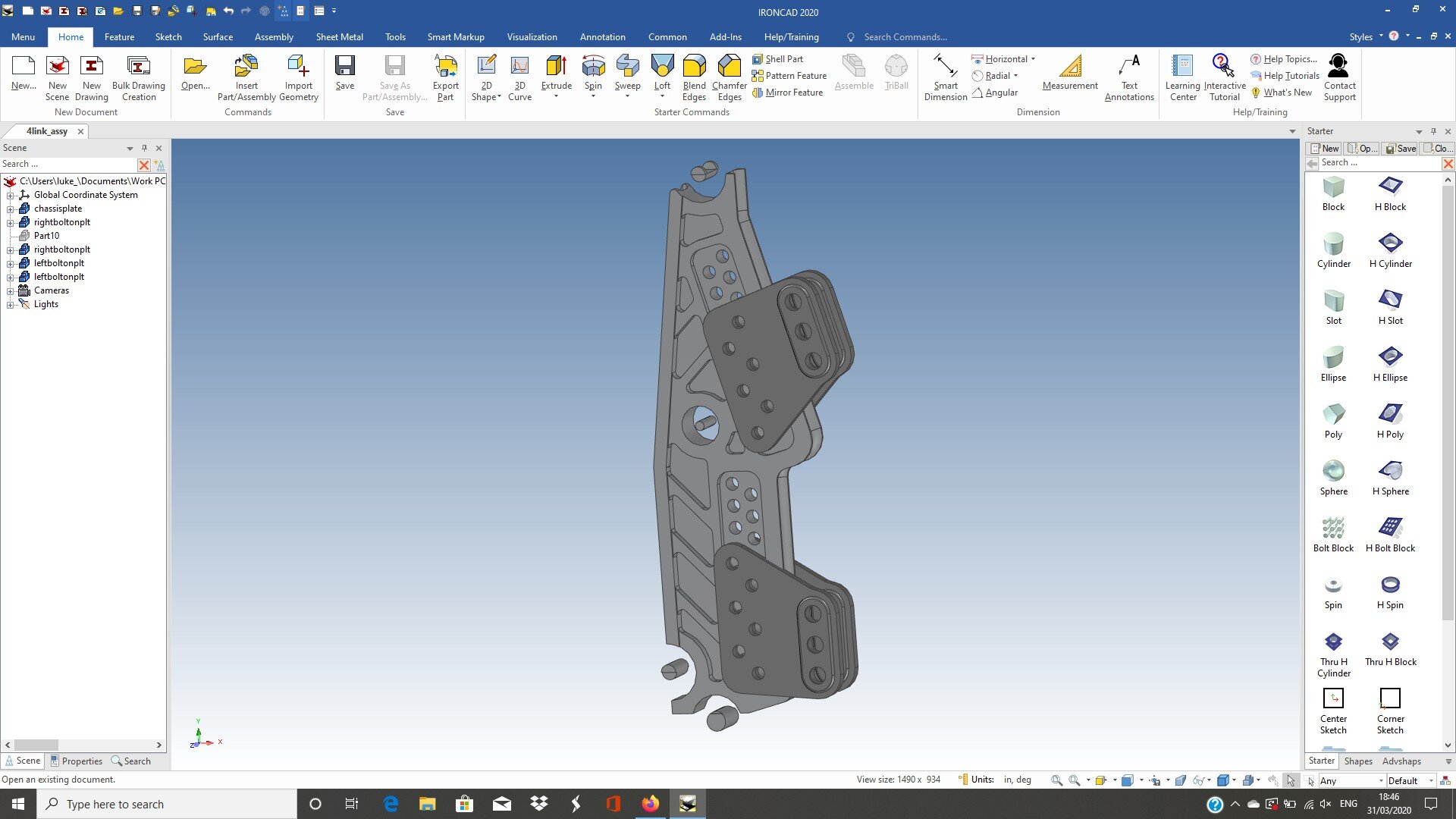

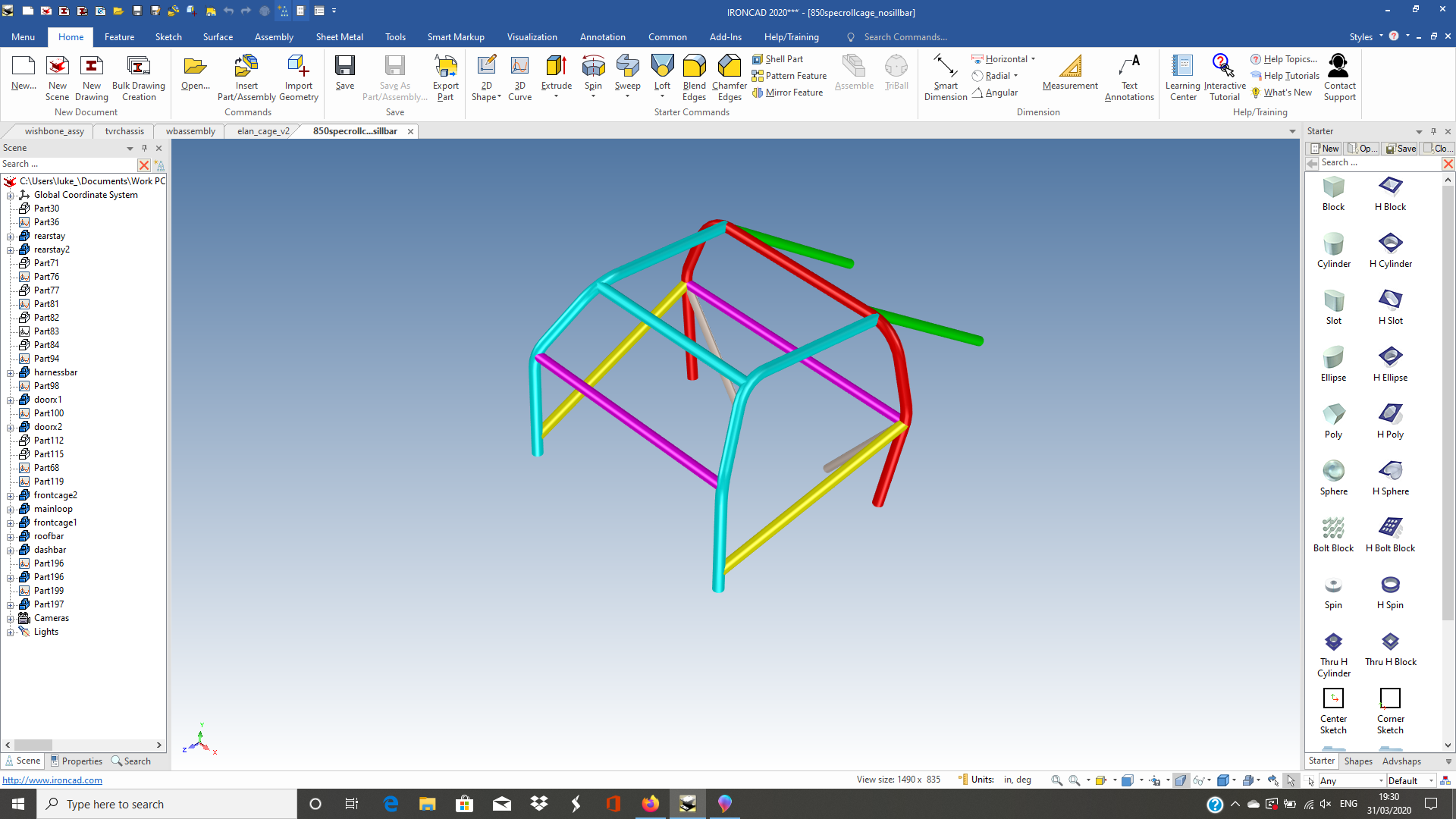

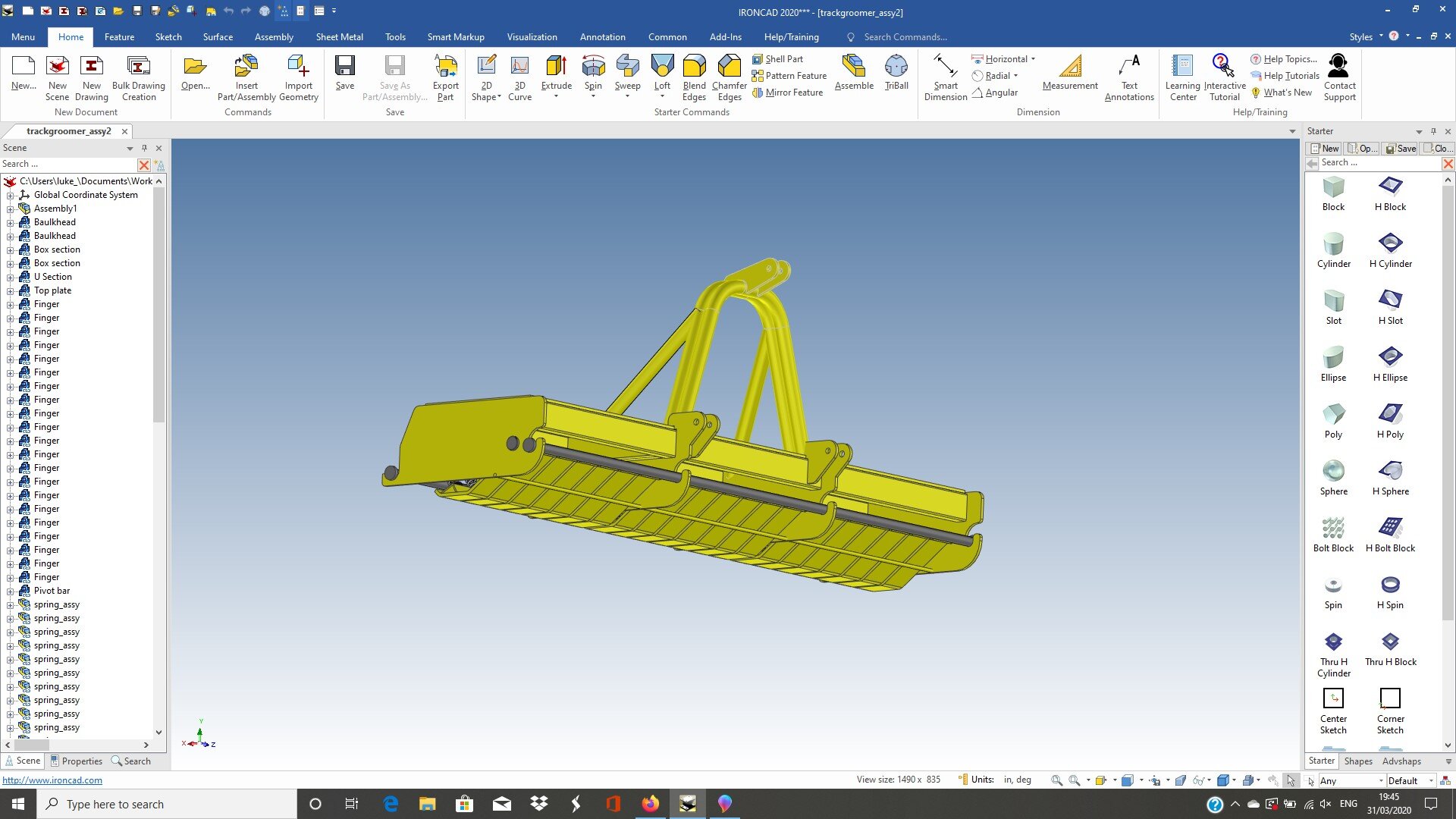

Items we have designed using IronCad include:

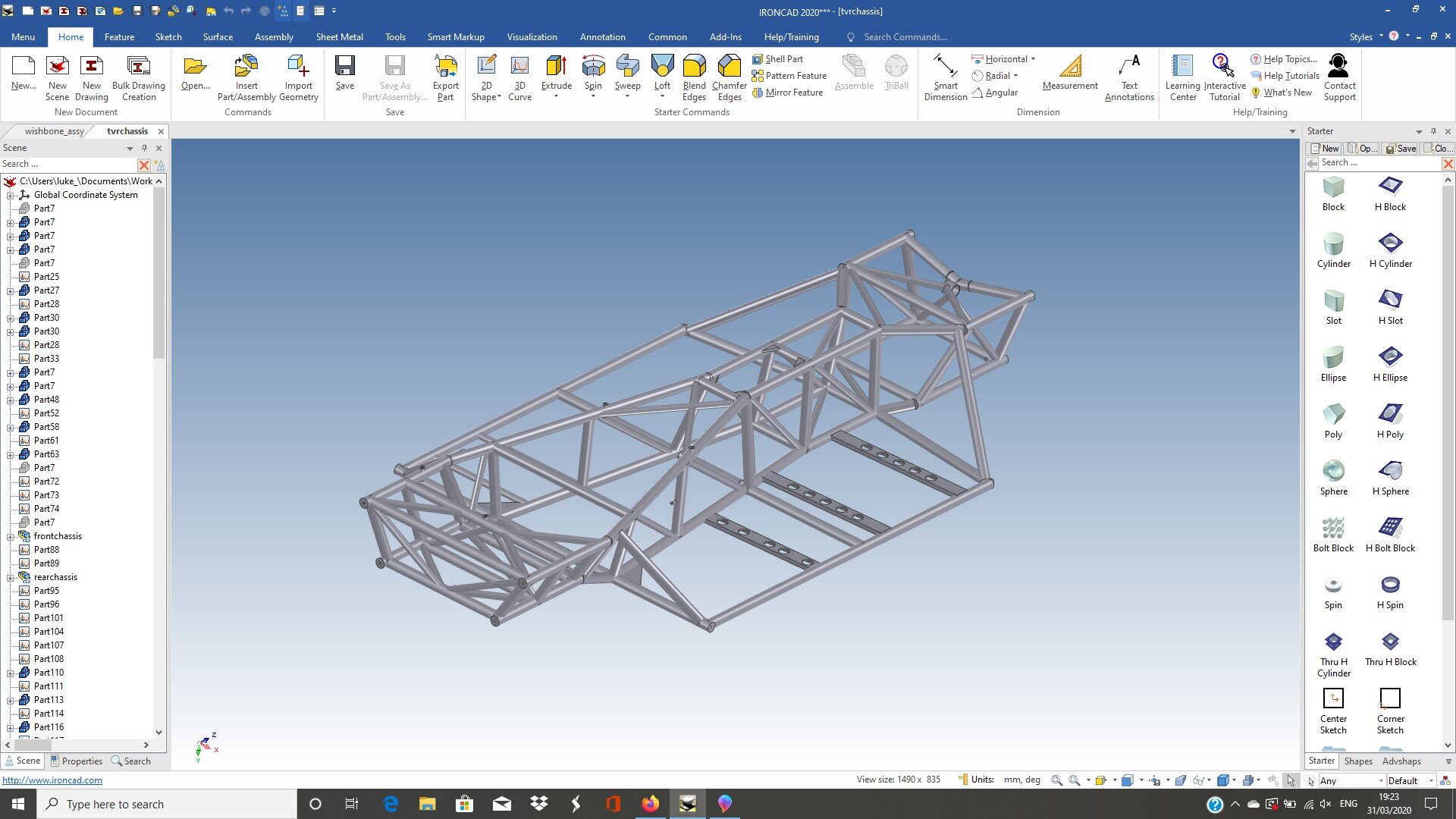

Tubular Spaceframes (click here to learn more)

Box section chassis and 'back half' chassis

Roll cages (click here to learn more)

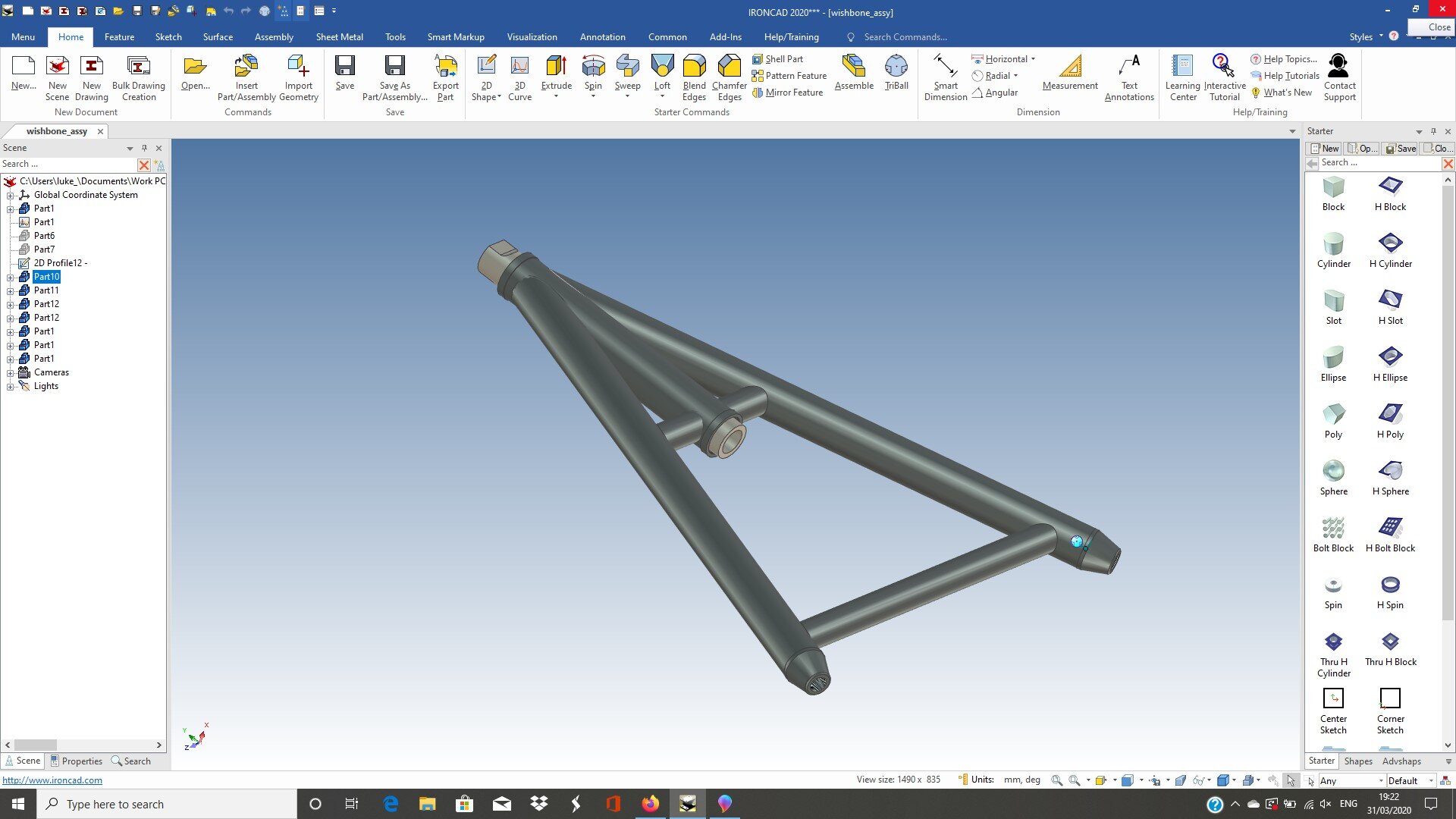

Suspension wishbones

4 link systems including our billet 'Max Adjust' system

Bracketry

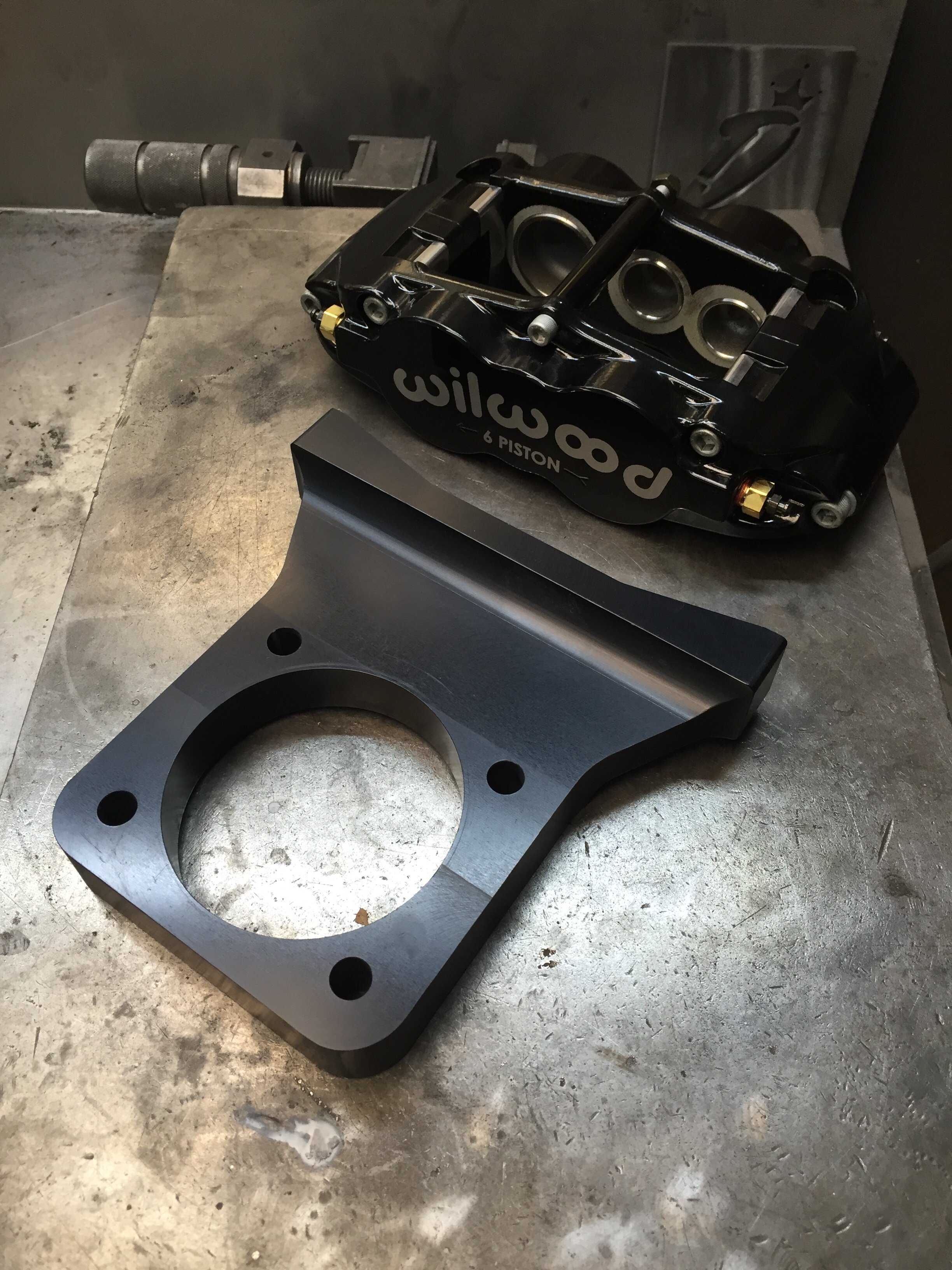

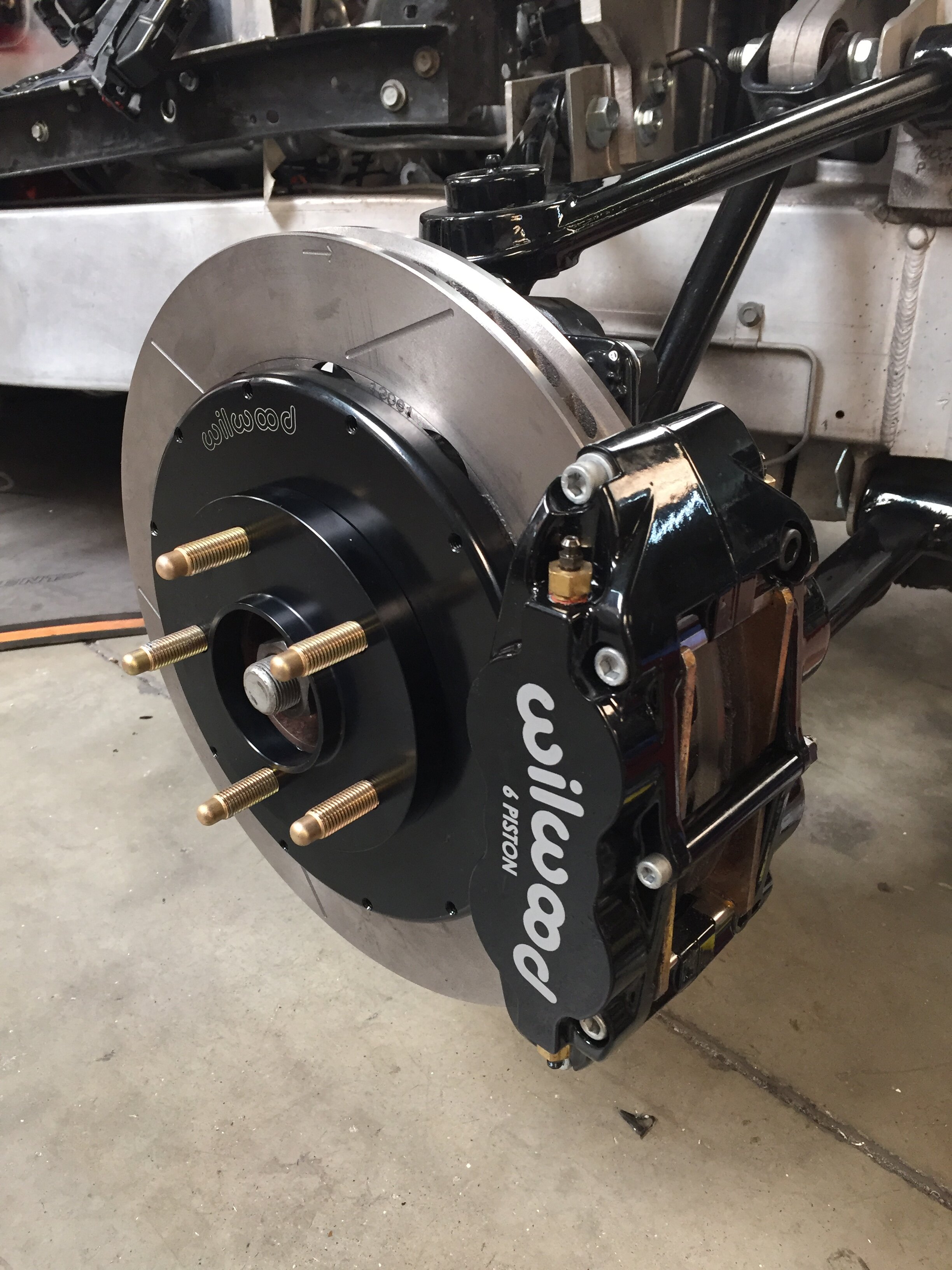

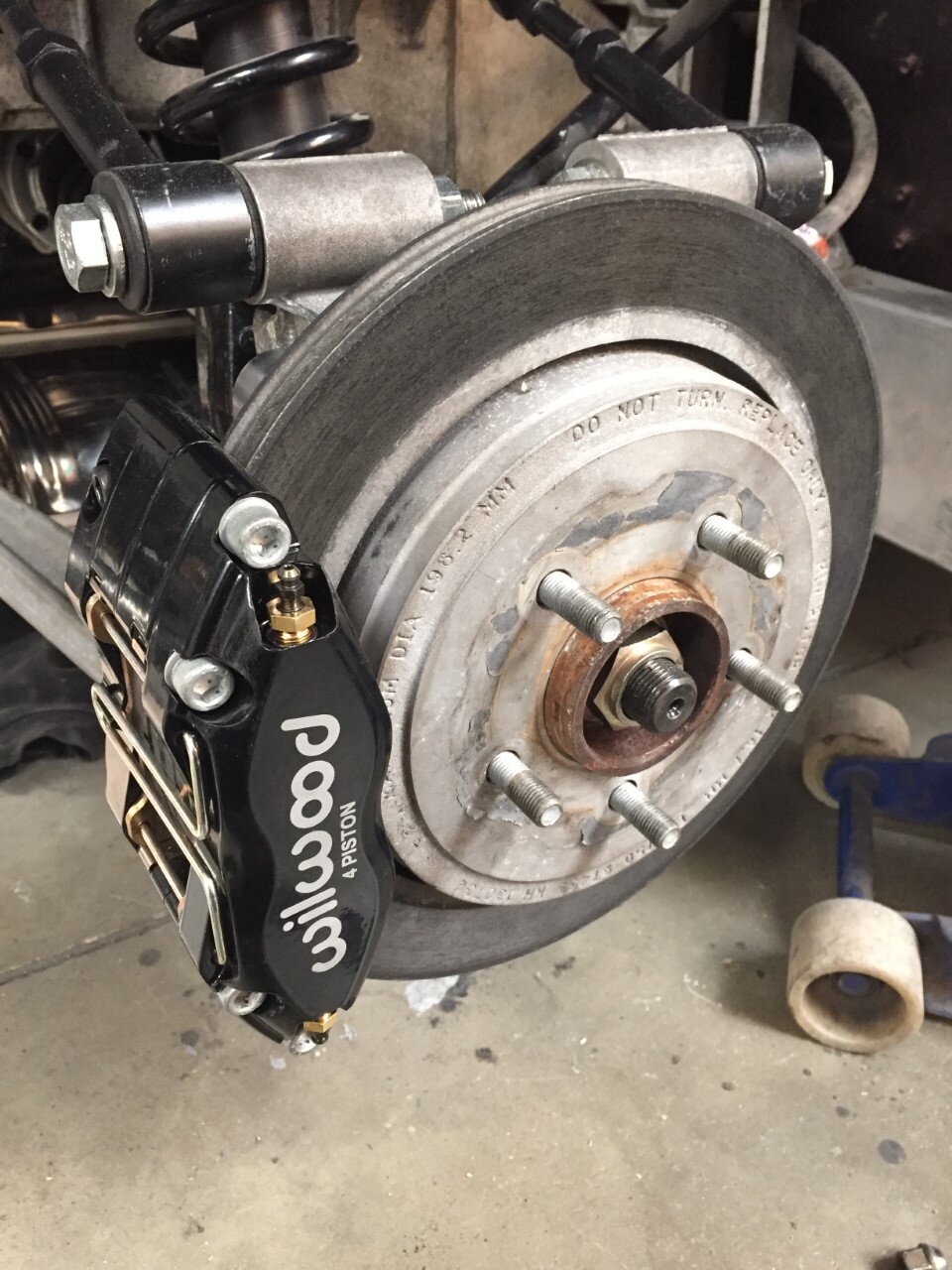

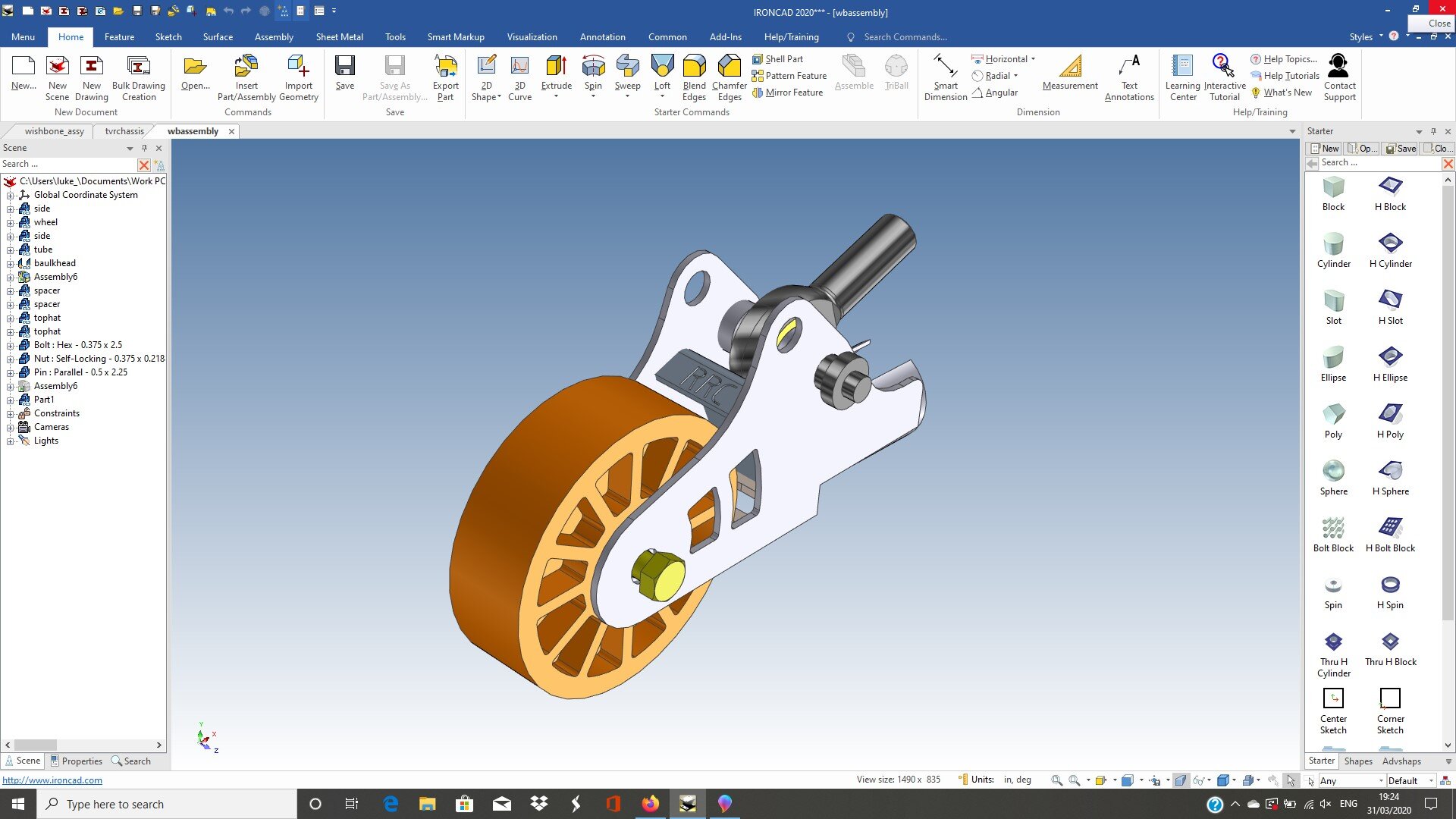

Brake caliper mount systems and rotor bells

Adaptor plates for various applications

We can also fabricate using 3D models and drawings from customers. A typical example is this Formula Student chassis.

In addition to IronCad, we use other software to facilitate our design work:

Bend Tech to compute tubing bend angles which we then input into our NC tube bender

Fourlink to calculate suspension geometry for drag racing applications including Instant Centre, C of G location, Anti-squat % etc.

Suspension Analyser to calculate suspension geometry for fast road and circuit cars, including anti squat %, anti dive %, dynamic toe change, dynamic camber change, dynamic castor change etc.

Finite Element Analysis to analyse our designs, minimising high stress/strain areas and evaluating them for production.